Our High-Tension Electrostatic Separators have been fundamental in minerals processing and recycling since the 1950’s

Originally designed by Carpco® in the mid 20th century, Outotec® brand electrostatic separators are the culmination of an extensive, several decade long development program dedicated to providing high-capacity They are designed to process coarse particles and difficult-to-separate materials in both the minerals and recycling industries.

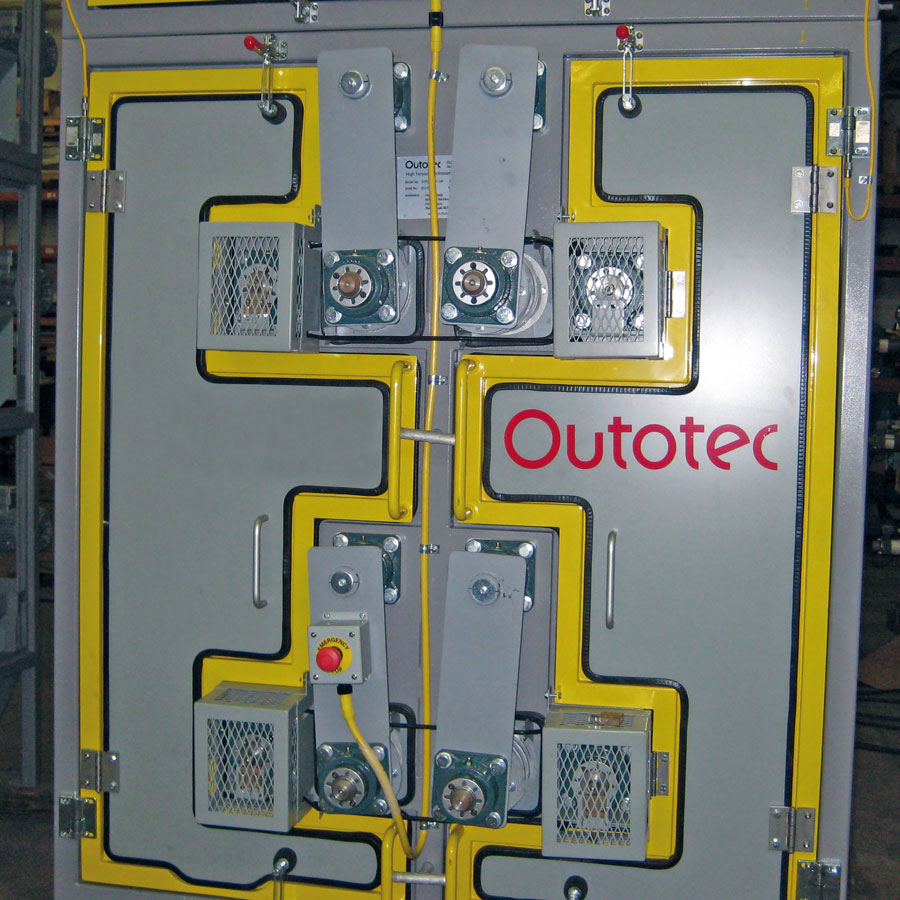

High-Tension Electrostatic Separators

Electrostatic Separation of Minerals

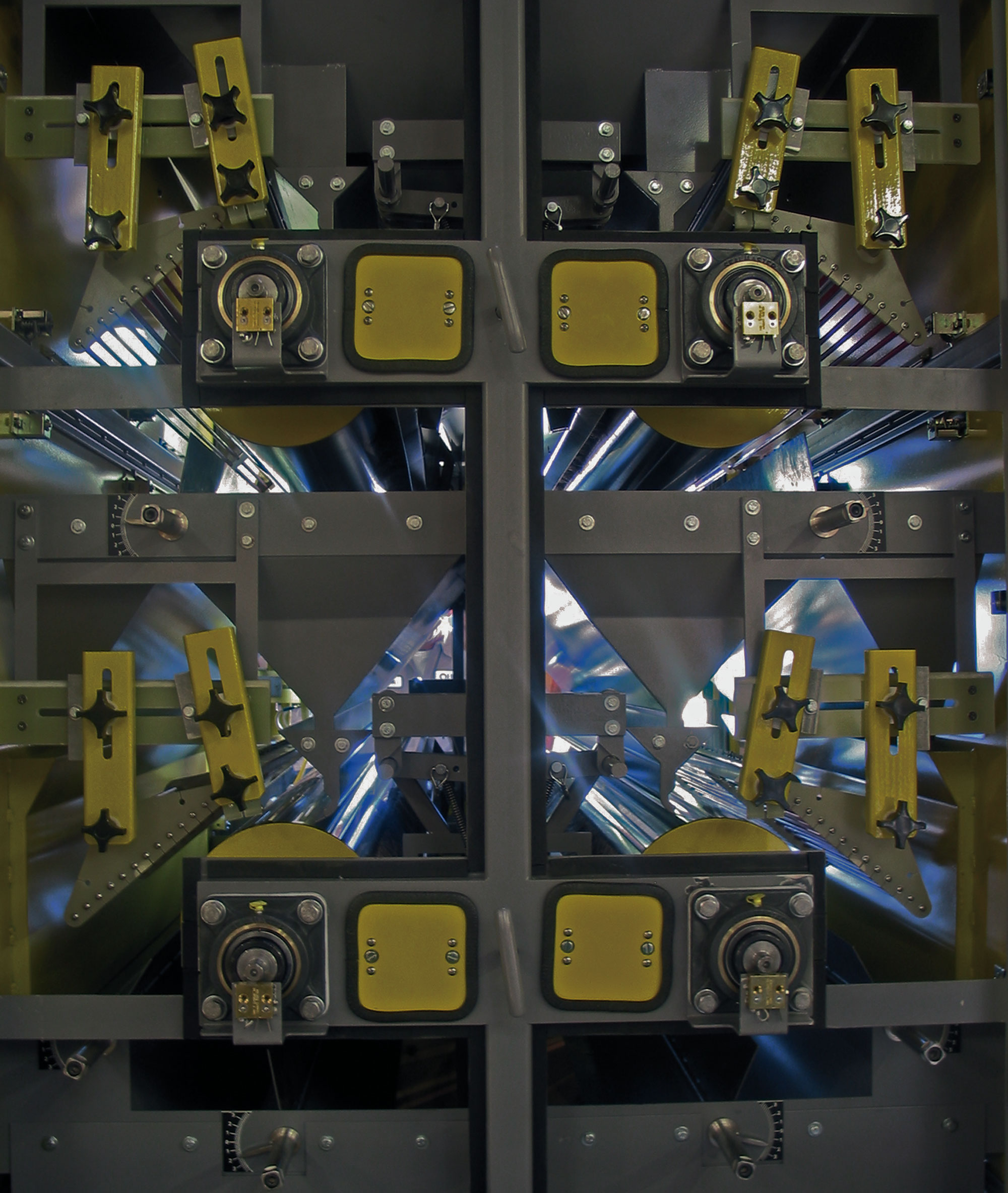

The Outotec® line of high-tension electrostatic separators utilize the difference in surface conductivity, surface charge and shape factors of particles to achieve separation. In general, this technique is used for conductor and non-conductor separation. They are most popular in mineral sands applications for the separation of ilmenite and rutile (conductors) from zircon and quartz (non-conductors). The tried and true separators incorporate numerous industry tested advanced features to maximize separation efficiency and capacity.

Electrostatic Separation In Recycling

Electrostatic separators are also well suited for a number of separation solutions in the recycling market. Using Outotec® High-Tension Roll Separators, plastics and metals can be recovered from scrap wire and cable, while plastics, metals and glass can be recovered from electronic and computer scrap.