Laboratory Rare Earth Roll Magnetic Separators

Directly Scale Your Feed to Commercial Machines for Minerals Concentration

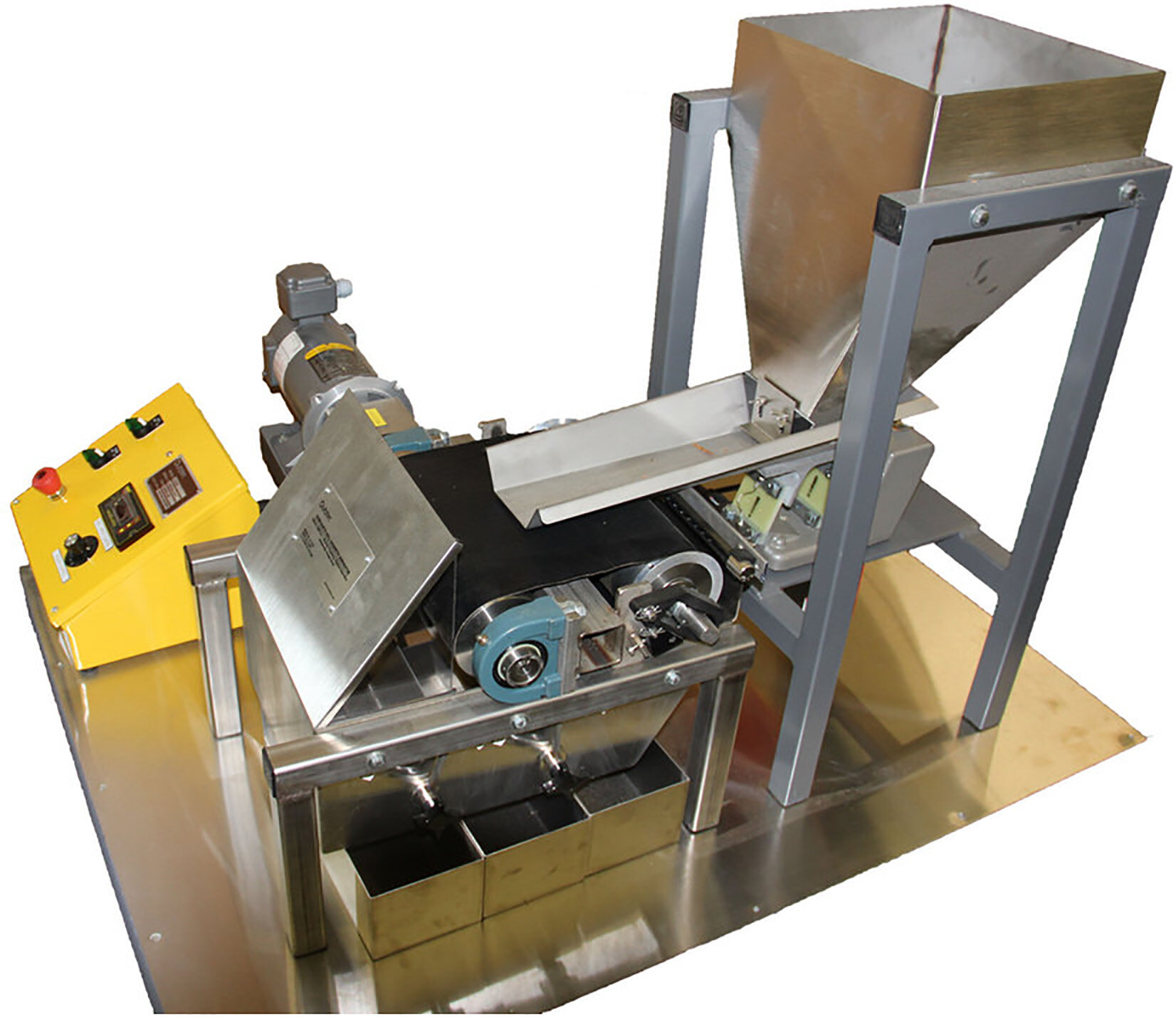

Outotec® Laboratory Magnetic Roll separator is designed to separate materials with a 100mm (4”) or 150mm (6”) diameter roll cassette diameter roll cassette. The magnetic zone is 200mm wide and available in several magnetic roll configurations. The magnetic roll is made with the highest strength Neodymium magnets. Unit includes hopper system and two splitters of stainless steel and frame construction of stainless steel.

The Outotec® laboratory magnetic roll separator performance can be directly scaled for your feed to commercial machines. Separation is optimized with proper selection of magnetic roll design, belt thickness, roll speed, splitter position, number of stages of separation and depth of the feed material on the belt, i.e. unit capacity.

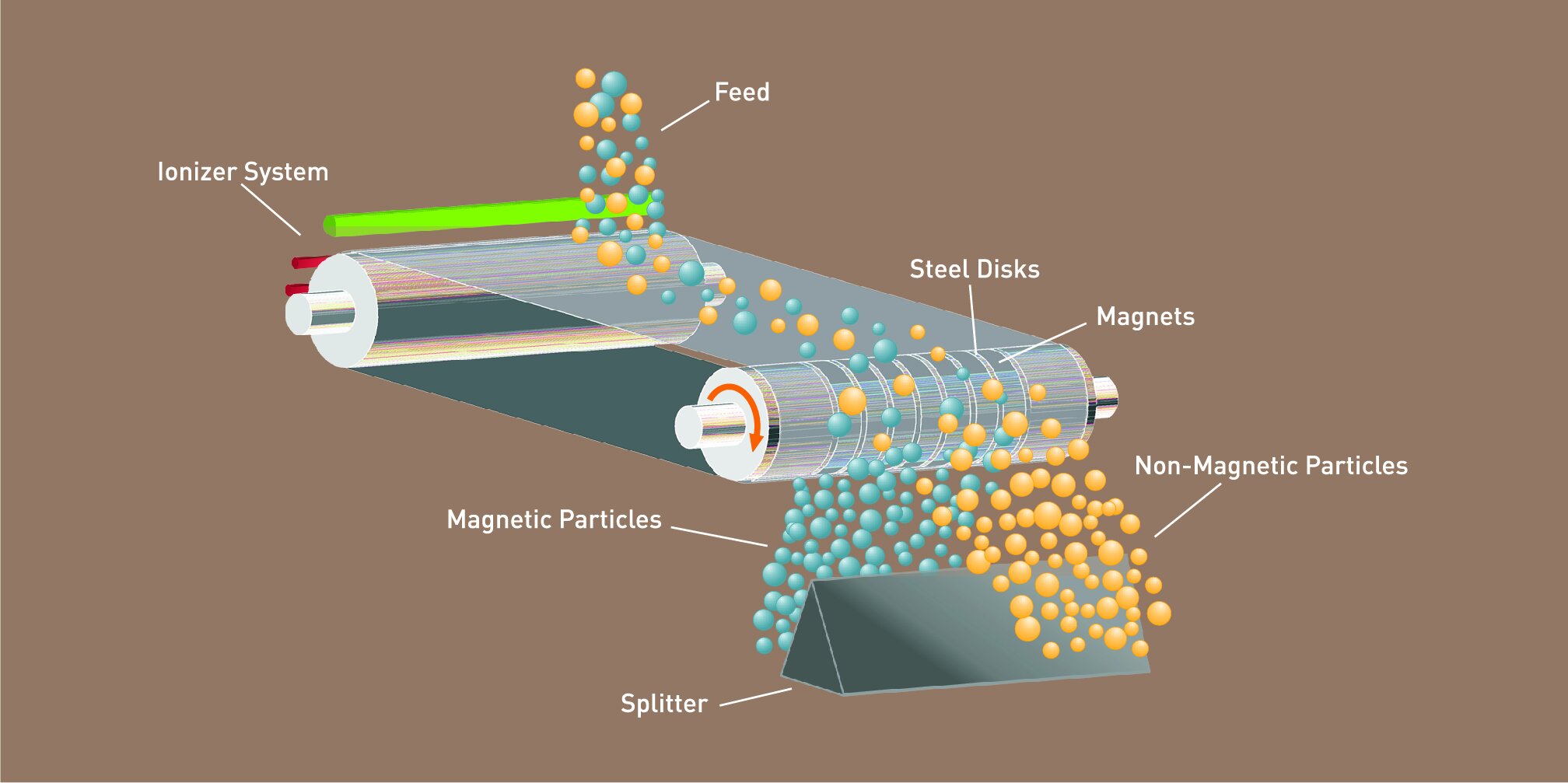

Magnetic Roll Separator Operation

Material is fed evenly onto the separator belt and is transported over a magnetic roll of unique design. As the feed material moves through the magnetic field all magnetic (including weakly magnetic) particles are attracted to the roll. Depending on the magnetic susceptibility of the particle it either:

Becomes attached to the surface of the belt and is subsequently released as it travels away from the magnetic field;

or

Is drawn toward the belt and its trajectory is altered from that of the nonmagnetic particles as they are thrown from the rotating roll.

This separator can operate continuously and has a variable speed drive system. It includes closed loop speed control to maintain roll speed at desired setting and a digital RPM read-out. The vibratory feeder is mounted in the frame along with the unit’s feeder.

MAGNETIC INTENSITY CONTROLLED BY THREE VARIABLES

Magnetic roll configuration: Supplied in about 15-20 different configurations to optimize the separation with various applications.

Magnetic roll speed: The magnetic roll speed controls the potential energy of the particles. Higher roll speeds create a competing force to the magnetic roll that produce great trajectories for particle separation

Belt Thickness: The thicker the belt, the less the magnetic strength is at the belt surface.

Minerals and materials applications

Andalusite

Manganese

Alumina

Magnesite

Bauxite

Micaceous hematite

Borate

Mulite

Bone Flour

Monazite

Barite

Nepheline syenite

Bentonite

Nickle laterite

Calcined bauxite

Phosphate ore

Calcium carbonate

Perlite

Chromite ore

Pigments

Chamotte

Potash

Clay

Pyrophyllite

Cullets

Quartz/Quartzite

Ditomaceous earth

Quartz

Diamonds

Rare-earth ores

Dunite

Rutile

Feldspar

Rock salt

Fluorspar

Radionuclides

Garnet

Silica

Gold

Scandium ore

Graphite

Sodium sulphate

Ilmenite

Spodumene

Iron ore

Talc

Kaolin

Trona

Kyanite

Vermiculite

Leucoxene

Wollastonite

Limestone

Zircon